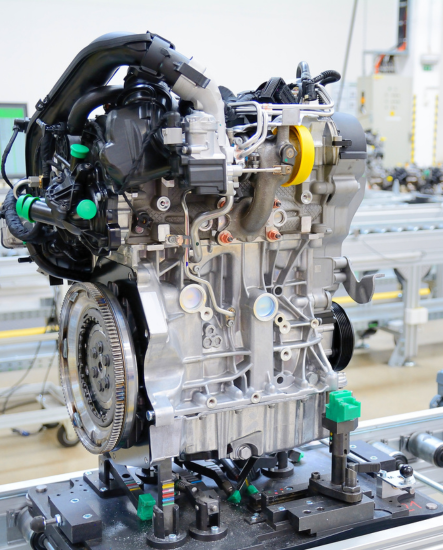

For more than a century, General Motors (GM) has been a prominent player in the global automotive industry, producing iconic vehicles and pioneering innovations. To maintain its manufacturing excellence, GM relies on a vast network of 4,000 suppliers who provide the tools necessary to produce automotive parts. These tools have life cycles of up to 20 years and range in size from very small to several tons.

Tracking and managing proprietary off-site production equipment posed a significant challenge for GM and its suppliers until they adopted RFID and Bluetooth Low Energy (BLE) technologies.

Suppliers had to perform time-consuming manual data entry to track tools.

Traditional methods often resulted in low first-time recognition rates and lengthy identification times.

Inefficient tracking processes negatively impacted productivity and caused delays.

Come in a variety of sizes and frequently change locations within manufacturing environments.

Are exposed to harsh conditions, including extreme temperatures and high-temperature processes.

Have life cycles of up to 20 years, making effective tracking and management critical.

To date, the system has documented 800,000 tools, with suppliers adding 60,000 to 100,000 new tools annually.

Each tool is assigned a unique ID number in SAP, accompanied by at least two photographs. Labels include the mandatory identifiers: “Property of GM” and the ID number.

Tool identification time was reduced by 85%.

The first-time targeting rate reached 98%, even in challenging manufacturing conditions.

The new system improved supplier efficiency and significantly reduced manpower requirements.

RFID and BLE technologies provided a cost-effective solution compared to other alternatives.

Insights from the pilot project are guiding further refinements to the tool tracking system.

Your trusted partner for premium RFID solutions